Release time:2022-04-26

What is the mold? Many people may not know much about it, but manufacturers are the ones who have more contact with it. In fact, although many people do not have direct contact with molds, many products used in people's daily life are made of molds. For example, military computer tables, medical equipment, projector lenses, etc., and the production of these products must also be inseparable from the processing technology, thenMold processingWhat are the processes?

Mold processing will carry out a variety of processes, and each process must be completed according to a certain law, so as to ensure that the mold can guarantee high quality and meet people's use needs. The following describes the mold processing technology.

1、 Mold processing procedure

1. We need to do a good job in production guidance. When processing products, we should plan and arrange production in advance, train all personnel in operating skills, and carry out quality inspection and cost accounting for workpieces. These should be carried out in accordance with the manufacturing process specification.

2. Prepare for production. When the workshop is going to produce new parts, it is necessary to formulate the machining process procedures of parts and prepare for production according to the manufacturing procedures.

3. In the case of a new factory, the type and quantity of machine tools and their placement in the workshop should be determined according to the process procedures, and the type of work and technical level should be equipped according to the actual situation of the workshop.

2、 Mold processing process flow

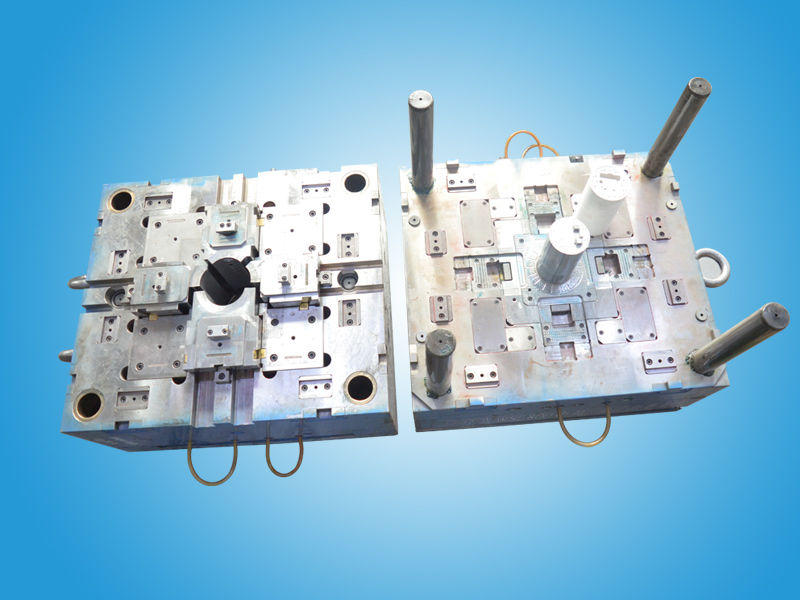

Generally, the technological process of mold processing is drawing review - material preparation - processing - mold base processing - mold core processing - electrode processing - mold part processing - Inspection - assembly - flying mold - trial mold - production. Usually, the customer will provide samples or 3D or 2D drawings. If the customer provides samples, the mold manufacturer will draw 3D drawings based on the samples, and the customer will directly send the 3D drawings, so the mold manufacturer will review them. After the review, we will reach a consensus with the customer, and then order the mold blank and internal mold steel, followed by 3D parting drawing. The completion of the whole mold generally takes about 15-20 days. During mold making, it is necessary to track the mold progress and make records. In short, mold processing is an art, which involves many processes.

3、 The important role of Mold Engineer

Mold manufacturing depends on mold engineers, who implement customized mold solutions for the entire project, design products, and draw mold parts and assembly drawings. In addition, they design and compile the mold processing technology, and timely solve the machining process problems in production. At the same time, they will develop new products, new processes, design new molds, and sort out and classify drawings and technical data.

The whole process of mold processing requires a lot of energy and time, and relevant process regulations are needed to standardize and implement. At the same time, strict technological process is also needed to complete the manufacturing of molds. Mold engineers play an important role in the manufacturing of molds one by one.