Release time:2024-01-03

Due to the special structure of the plastic surface, although the surface of the plastic parts is modified by surface pretreatment, the weak interface layer is removed, the surface of the plastic parts is activated, and the adhesion of the coating film is increasedPlastic shellIn the manufacturing process, the choice of coating, coating process and coating environment management will also affect the coating quality.

Therefore, the selection of mechanical plastic shell coating shall follow the principle of "similar miscibility". The good miscibility of ABS with coating resin and solvent shall be utilized to form a layer of miscible thin layer between the coating film and plastic surface to enhance adhesion. It shall not only have good decorative property, but also meet the requirements of physical and chemical properties of the paint film.

At present, the artificial air spraying process is mostly used for the coating of mechanical plastic casings. The labor intensity is large, the working environment is poor, the coating efficiency is only about 20% ~ 30%, the coating loss is large, the cost is high, and the unstable factors caused by man directly affect the product quality.

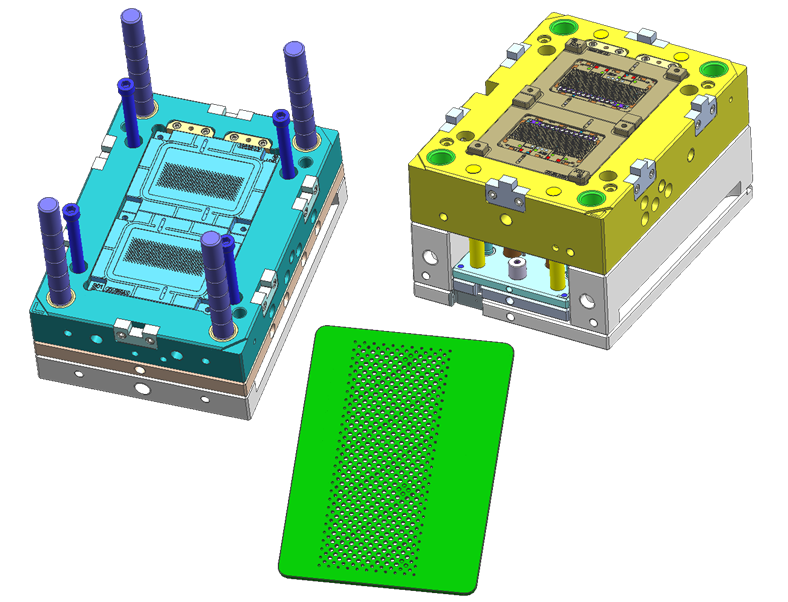

With the development of science and technology, the in mold coating in the mechanical plastic shell manufacturing industry has developed rapidly in the plastic processing, that is, the electrostatic coating is applied to the inner wall of the mold, and the surface coating of the plastic parts is completed at the same time when the plastic is molded. Because the plastic molding temperature is high, which is conducive to the curing of the coating, and the roughness of the mold itself is low, the coating surface is smooth and the gloss is high.

After the mechanical plastic shell is molded, lift the mold slightly, inject high pressure into the IMC, and close the mold tightly, so that the IMC is fully expanded. After hardening, the film is removed. The plastic surface is very flat and smooth, and high-quality decorative products can be obtained at low cost. The molded parts can be immediately packed or sent for assembly, which is very convenient.

The coatings used in the two coating processes of the mechanical plastic shell are solvent-free coatings. There is no organic solvent emission during the operation, so there is no environmental pollution. Moreover, the utilization rate of the coatings is high, which avoids heavy coating operations and does not require special coating equipment. Therefore, the coating can be completed at the time of injection molding.